Wooden Windows

Our wooden windows and doors meet high architectural, energy, and environmental standards.

We offer three levels of frames: R62, R68, and R78, which ensure the best possible performance in terms of both durability and energy efficiency.

Our wooden windows and doors meet high architectural, energy, and environmental criteria.

We offer three levels of framing: R62, R68, and R78, which ensure the best possible performance in terms of both durability and energy efficiency.

Our wooden windows and doors meet high architectural, energy, and environmental standards.

We offer three levels of frames: R62, R68, and R78, which ensure the best possible performance, both in terms of durability and energy efficiency.

Our wooden windows and doors meet high architectural, energy, and environmental standards.

We offer three levels of frames: R62, R68, and R78, which ensure the best possible performance, both in terms of durability and energy efficiency.

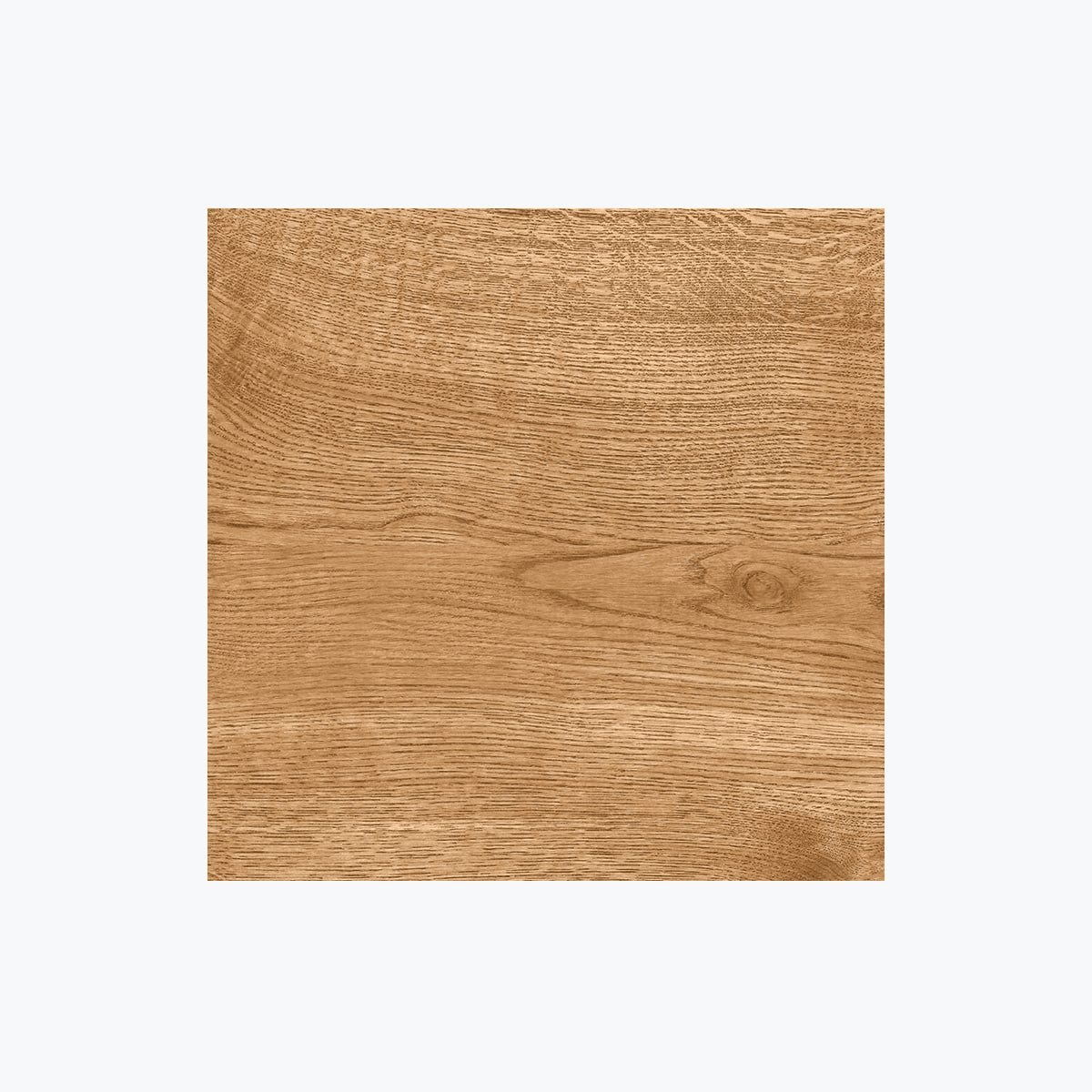

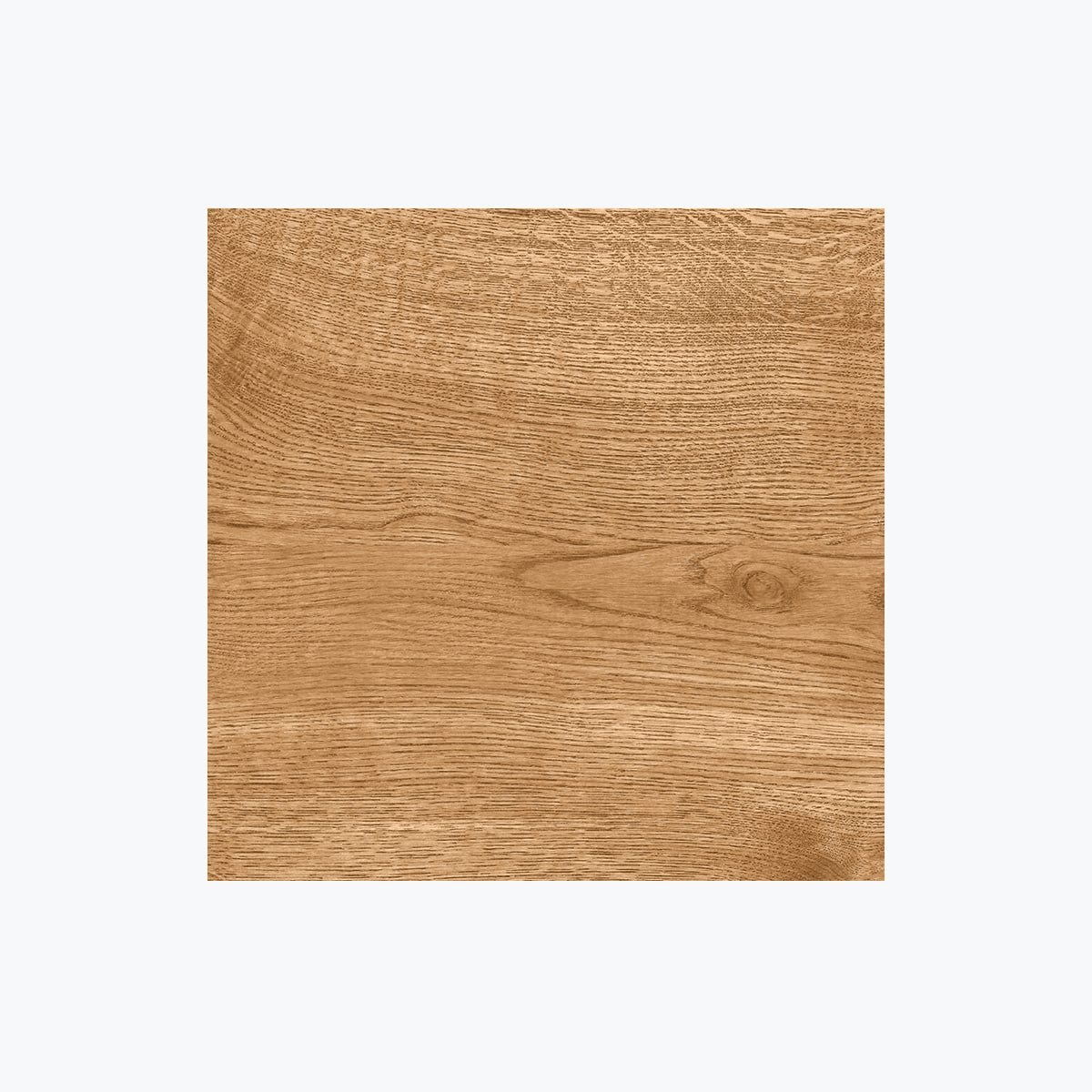

Wood variants

Pine

Fir

Meranti

Oak

Wood variants

Pine

Fir

Meranti

Oak

Wood variants

Pine

Fir

Meranti

Oak

Wood variants

Pine

Fir

Meranti

Oak

Cut drawing

In the production of wooden windows and doors, the most commonly used is what is called glued laminated wood, made up of 3 or 4 layers. This solution:

increases the stability of the window or door;

prevents deformations caused by humidity;

allows the creation of windows with different shapes (arched, round).

There are two types of plywood available on the market: solid and with micro-joints.

Solid plywood (solid pine)

The solid plywood is mainly designed for windows and doors where light (transparent) coatings are used. The most important thing is that there are no joints in this plywood and the material is selected to obtain the largest possible sections of defect-free wood.

Laminated wood glued with micro-connectors (micro-pine)

For laminated glued wood with micro-joints, cut sections of solid wood are used. Only elements without natural defects are selected. One characteristic is a visible connection along the entire length through the so-called micro-cavities. Therefore, due to the lower aesthetic value, its surface is typically covered with opaque paints.

Cut drawing

In the production of wooden windows and doors, the most commonly used is what is called glued laminated wood, made up of 3 or 4 layers. This solution:

increases the stability of the window or door;

prevents deformations caused by humidity;

allows the creation of windows with different shapes (arched, round).

There are two types of plywood available on the market: solid and with micro-joints.

Solid plywood (solid pine)

The solid plywood is mainly designed for windows and doors where light (transparent) coatings are used. The most important thing is that there are no joints in this plywood and the material is selected to obtain the largest possible sections of defect-free wood.

Laminated wood glued with micro-connectors (micro-pine)

For laminated glued wood with micro-joints, cut sections of solid wood are used. Only elements without natural defects are selected. One characteristic is a visible connection along the entire length through the so-called micro-cavities. Therefore, due to the lower aesthetic value, its surface is typically covered with opaque paints.

Cut drawing

In the production of wooden windows and doors, the most commonly used is what is called glued laminated wood, made up of 3 or 4 layers. This solution:

increases the stability of the window or door;

prevents deformations caused by humidity;

allows the creation of windows with different shapes (arched, round).

There are two types of plywood available on the market: solid and with micro-joints.

Solid plywood (solid pine)

The solid plywood is mainly designed for windows and doors where light (transparent) coatings are used. The most important thing is that there are no joints in this plywood and the material is selected to obtain the largest possible sections of defect-free wood.

Laminated wood glued with micro-connectors (micro-pine)

For laminated glued wood with micro-joints, cut sections of solid wood are used. Only elements without natural defects are selected. One characteristic is a visible connection along the entire length through the so-called micro-cavities. Therefore, due to the lower aesthetic value, its surface is typically covered with opaque paints.

Cut drawing

In the production of wooden windows and doors, the most commonly used is what is called glued laminated wood, made up of 3 or 4 layers. This solution:

increases the stability of the window or door;

prevents deformations caused by humidity;

allows the creation of windows with different shapes (arched, round).

There are two types of plywood available on the market: solid and with micro-joints.

Solid plywood (solid pine)

The solid plywood is mainly designed for windows and doors where light (transparent) coatings are used. The most important thing is that there are no joints in this plywood and the material is selected to obtain the largest possible sections of defect-free wood.

Laminated wood glued with micro-connectors (micro-pine)

For laminated glued wood with micro-joints, cut sections of solid wood are used. Only elements without natural defects are selected. One characteristic is a visible connection along the entire length through the so-called micro-cavities. Therefore, due to the lower aesthetic value, its surface is typically covered with opaque paints.

Gallery

What our clients say:

We agreed to use aluminum windows with the Schüco profile, one of the most prestigious profile systems, and we have not regretted this choice at any moment. About a month after the contract was signed, the installation process began. I would also like to highlight that the company is part of the state program Class+, which allowed us to be reimbursed nearly 2000 euros for the replacement of the windows. This company is truly advantageous and professional.

– Diogo Fernandes

I was pleasantly surprised by the level of service and the quality of the windows. We opted for conventional PVC windows. The price was approximately the same as that of other competing companies. We chose MaxiGlass because they responded quickly and offered a 10-year warranty with no additional maintenance costs. We have already noticed a 20% reduction in energy expenses. I regret not replacing the old windows earlier.

– Manuela Ferreira

I am grateful to the team at MaxiGlass. I would especially like to highlight the manager Olesya. She was very helpful and professional. I chose Aluprof aluminum windows for my country house, as they suited the project design better. These windows have a very elegant and modern look. I also immediately noticed a good level of sound insulation. Thank you for the quality work and careful installation.

– Bruno Coutinho

Our apartment is located in the historic center of Lisbon, and it was important to preserve the architectural style of the building. The windows fit perfectly into our interior decor. However, the main advantage was the efficiency. We are happy that the team truly dedicated themselves to our project and managed to install the windows in less than a month.

– Sergio Farinha

We were updating the windows for a building used as an Airbnb hotel in Ponta Delgada. Aesthetics were important to us, so we chose to install Reynaers aluminum windows. They withstand the aggressive maritime climate very well and have a high level of energy efficiency. Moreover, we were very pleased with the communication with the managers. It was welcoming and professional.

– Fia Gonçalves

We agreed to use aluminum windows with the Schüco profile, one of the most prestigious profile systems, and we have not regretted this choice at any moment. About a month after the contract was signed, the installation process began. I would also like to highlight that the company is part of the state program Class+, which allowed us to be reimbursed nearly 2000 euros for the replacement of the windows. This company is truly advantageous and professional.

– Diogo Fernandes

I was pleasantly surprised by the level of service and the quality of the windows. We opted for conventional PVC windows. The price was approximately the same as that of other competing companies. We chose MaxiGlass because they responded quickly and offered a 10-year warranty with no additional maintenance costs. We have already noticed a 20% reduction in energy expenses. I regret not replacing the old windows earlier.

– Manuela Ferreira

I am grateful to the team at MaxiGlass. I would especially like to highlight the manager Olesya. She was very helpful and professional. I chose Aluprof aluminum windows for my country house, as they suited the project design better. These windows have a very elegant and modern look. I also immediately noticed a good level of sound insulation. Thank you for the quality work and careful installation.

– Bruno Coutinho

Our apartment is located in the historic center of Lisbon, and it was important to preserve the architectural style of the building. The windows fit perfectly into our interior decor. However, the main advantage was the efficiency. We are happy that the team truly dedicated themselves to our project and managed to install the windows in less than a month.

– Sergio Farinha

We were updating the windows for a building used as an Airbnb hotel in Ponta Delgada. Aesthetics were important to us, so we chose to install Reynaers aluminum windows. They withstand the aggressive maritime climate very well and have a high level of energy efficiency. Moreover, we were very pleased with the communication with the managers. It was welcoming and professional.

– Fia Gonçalves

We agreed to use aluminum windows with the Schüco profile, one of the most prestigious profile systems, and we have not regretted this choice at any moment. About a month after the contract was signed, the installation process began. I would also like to highlight that the company is part of the state program Class+, which allowed us to be reimbursed nearly 2000 euros for the replacement of the windows. This company is truly advantageous and professional.

– Diogo Fernandes

I was pleasantly surprised by the level of service and the quality of the windows. We opted for conventional PVC windows. The price was approximately the same as that of other competing companies. We chose MaxiGlass because they responded quickly and offered a 10-year warranty with no additional maintenance costs. We have already noticed a 20% reduction in energy expenses. I regret not replacing the old windows earlier.

– Manuela Ferreira

I am grateful to the team at MaxiGlass. I would especially like to highlight the manager Olesya. She was very helpful and professional. I chose Aluprof aluminum windows for my country house, as they suited the project design better. These windows have a very elegant and modern look. I also immediately noticed a good level of sound insulation. Thank you for the quality work and careful installation.

– Bruno Coutinho

Our apartment is located in the historic center of Lisbon, and it was important to preserve the architectural style of the building. The windows fit perfectly into our interior decor. However, the main advantage was the efficiency. We are happy that the team truly dedicated themselves to our project and managed to install the windows in less than a month.

– Sergio Farinha

We were updating the windows for a building used as an Airbnb hotel in Ponta Delgada. Aesthetics were important to us, so we chose to install Reynaers aluminum windows. They withstand the aggressive maritime climate very well and have a high level of energy efficiency. Moreover, we were very pleased with the communication with the managers. It was welcoming and professional.

– Fia Gonçalves

We agreed to use aluminum windows with the Schüco profile, one of the most prestigious profile systems, and we have not regretted this choice at any moment. About a month after the contract was signed, the installation process began. I would also like to highlight that the company is part of the state program Class+, which allowed us to be reimbursed nearly 2000 euros for the replacement of the windows. This company is truly advantageous and professional.

– Diogo Fernandes

I was pleasantly surprised by the level of service and the quality of the windows. We opted for conventional PVC windows. The price was approximately the same as that of other competing companies. We chose MaxiGlass because they responded quickly and offered a 10-year warranty with no additional maintenance costs. We have already noticed a 20% reduction in energy expenses. I regret not replacing the old windows earlier.

– Manuela Ferreira

I am grateful to the team at MaxiGlass. I would especially like to highlight the manager Olesya. She was very helpful and professional. I chose Aluprof aluminum windows for my country house, as they suited the project design better. These windows have a very elegant and modern look. I also immediately noticed a good level of sound insulation. Thank you for the quality work and careful installation.

– Bruno Coutinho

Our apartment is located in the historic center of Lisbon, and it was important to preserve the architectural style of the building. The windows fit perfectly into our interior decor. However, the main advantage was the efficiency. We are happy that the team truly dedicated themselves to our project and managed to install the windows in less than a month.

– Sergio Farinha

We were updating the windows for a building used as an Airbnb hotel in Ponta Delgada. Aesthetics were important to us, so we chose to install Reynaers aluminum windows. They withstand the aggressive maritime climate very well and have a high level of energy efficiency. Moreover, we were very pleased with the communication with the managers. It was welcoming and professional.

– Fia Gonçalves

What our clients say:

We agreed to use aluminum windows with the Schüco profile, one of the most prestigious profile systems, and we have not regretted this choice at any moment. About a month after the contract was signed, the installation process began. I would also like to highlight that the company is part of the state program Class+, which allowed us to be reimbursed nearly 2000 euros for the replacement of the windows. This company is truly advantageous and professional.

– Diogo Fernandes

I was pleasantly surprised by the level of service and the quality of the windows. We opted for conventional PVC windows. The price was approximately the same as that of other competing companies. We chose MaxiGlass because they responded quickly and offered a 10-year warranty with no additional maintenance costs. We have already noticed a 20% reduction in energy expenses. I regret not replacing the old windows earlier.

– Manuela Ferreira

I am grateful to the team at MaxiGlass. I would especially like to highlight the manager Olesya. She was very helpful and professional. I chose Aluprof aluminum windows for my country house, as they suited the project design better. These windows have a very elegant and modern look. I also immediately noticed a good level of sound insulation. Thank you for the quality work and careful installation.

– Bruno Coutinho

Our apartment is located in the historic center of Lisbon, and it was important to preserve the architectural style of the building. The windows fit perfectly into our interior decor. However, the main advantage was the efficiency. We are happy that the team truly dedicated themselves to our project and managed to install the windows in less than a month.

– Sergio Farinha

We were updating the windows for a building used as an Airbnb hotel in Ponta Delgada. Aesthetics were important to us, so we chose to install Reynaers aluminum windows. They withstand the aggressive maritime climate very well and have a high level of energy efficiency. Moreover, we were very pleased with the communication with the managers. It was welcoming and professional.

– Fia Gonçalves

We agreed to use aluminum windows with the Schüco profile, one of the most prestigious profile systems, and we have not regretted this choice at any moment. About a month after the contract was signed, the installation process began. I would also like to highlight that the company is part of the state program Class+, which allowed us to be reimbursed nearly 2000 euros for the replacement of the windows. This company is truly advantageous and professional.

– Diogo Fernandes

I was pleasantly surprised by the level of service and the quality of the windows. We opted for conventional PVC windows. The price was approximately the same as that of other competing companies. We chose MaxiGlass because they responded quickly and offered a 10-year warranty with no additional maintenance costs. We have already noticed a 20% reduction in energy expenses. I regret not replacing the old windows earlier.

– Manuela Ferreira

I am grateful to the team at MaxiGlass. I would especially like to highlight the manager Olesya. She was very helpful and professional. I chose Aluprof aluminum windows for my country house, as they suited the project design better. These windows have a very elegant and modern look. I also immediately noticed a good level of sound insulation. Thank you for the quality work and careful installation.

– Bruno Coutinho

Our apartment is located in the historic center of Lisbon, and it was important to preserve the architectural style of the building. The windows fit perfectly into our interior decor. However, the main advantage was the efficiency. We are happy that the team truly dedicated themselves to our project and managed to install the windows in less than a month.

– Sergio Farinha

We were updating the windows for a building used as an Airbnb hotel in Ponta Delgada. Aesthetics were important to us, so we chose to install Reynaers aluminum windows. They withstand the aggressive maritime climate very well and have a high level of energy efficiency. Moreover, we were very pleased with the communication with the managers. It was welcoming and professional.

– Fia Gonçalves

We agreed to use aluminum windows with the Schüco profile, one of the most prestigious profile systems, and we have not regretted this choice at any moment. About a month after the contract was signed, the installation process began. I would also like to highlight that the company is part of the state program Class+, which allowed us to be reimbursed nearly 2000 euros for the replacement of the windows. This company is truly advantageous and professional.

– Diogo Fernandes

I was pleasantly surprised by the level of service and the quality of the windows. We opted for conventional PVC windows. The price was approximately the same as that of other competing companies. We chose MaxiGlass because they responded quickly and offered a 10-year warranty with no additional maintenance costs. We have already noticed a 20% reduction in energy expenses. I regret not replacing the old windows earlier.

– Manuela Ferreira

I am grateful to the team at MaxiGlass. I would especially like to highlight the manager Olesya. She was very helpful and professional. I chose Aluprof aluminum windows for my country house, as they suited the project design better. These windows have a very elegant and modern look. I also immediately noticed a good level of sound insulation. Thank you for the quality work and careful installation.

– Bruno Coutinho

Our apartment is located in the historic center of Lisbon, and it was important to preserve the architectural style of the building. The windows fit perfectly into our interior decor. However, the main advantage was the efficiency. We are happy that the team truly dedicated themselves to our project and managed to install the windows in less than a month.

– Sergio Farinha

We were updating the windows for a building used as an Airbnb hotel in Ponta Delgada. Aesthetics were important to us, so we chose to install Reynaers aluminum windows. They withstand the aggressive maritime climate very well and have a high level of energy efficiency. Moreover, we were very pleased with the communication with the managers. It was welcoming and professional.

– Fia Gonçalves

We agreed to use aluminum windows with the Schüco profile, one of the most prestigious profile systems, and we have not regretted this choice at any moment. About a month after the contract was signed, the installation process began. I would also like to highlight that the company is part of the state program Class+, which allowed us to be reimbursed nearly 2000 euros for the replacement of the windows. This company is truly advantageous and professional.

– Diogo Fernandes

I was pleasantly surprised by the level of service and the quality of the windows. We opted for conventional PVC windows. The price was approximately the same as that of other competing companies. We chose MaxiGlass because they responded quickly and offered a 10-year warranty with no additional maintenance costs. We have already noticed a 20% reduction in energy expenses. I regret not replacing the old windows earlier.

– Manuela Ferreira

I am grateful to the team at MaxiGlass. I would especially like to highlight the manager Olesya. She was very helpful and professional. I chose Aluprof aluminum windows for my country house, as they suited the project design better. These windows have a very elegant and modern look. I also immediately noticed a good level of sound insulation. Thank you for the quality work and careful installation.

– Bruno Coutinho

Our apartment is located in the historic center of Lisbon, and it was important to preserve the architectural style of the building. The windows fit perfectly into our interior decor. However, the main advantage was the efficiency. We are happy that the team truly dedicated themselves to our project and managed to install the windows in less than a month.

– Sergio Farinha

We were updating the windows for a building used as an Airbnb hotel in Ponta Delgada. Aesthetics were important to us, so we chose to install Reynaers aluminum windows. They withstand the aggressive maritime climate very well and have a high level of energy efficiency. Moreover, we were very pleased with the communication with the managers. It was welcoming and professional.

– Fia Gonçalves

What our clients say:

We agreed to use aluminum windows with the Schüco profile, one of the most prestigious profile systems, and we have not regretted this choice at any moment. About a month after the contract was signed, the installation process began. I would also like to highlight that the company is part of the state program Class+, which allowed us to be reimbursed nearly 2000 euros for the replacement of the windows. This company is truly advantageous and professional.

– Diogo Fernandes

I was pleasantly surprised by the level of service and the quality of the windows. We opted for conventional PVC windows. The price was approximately the same as that of other competing companies. We chose MaxiGlass because they responded quickly and offered a 10-year warranty with no additional maintenance costs. We have already noticed a 20% reduction in energy expenses. I regret not replacing the old windows earlier.

– Manuela Ferreira

I am grateful to the team at MaxiGlass. I would especially like to highlight the manager Olesya. She was very helpful and professional. I chose Aluprof aluminum windows for my country house, as they suited the project design better. These windows have a very elegant and modern look. I also immediately noticed a good level of sound insulation. Thank you for the quality work and careful installation.

– Bruno Coutinho

Our apartment is located in the historic center of Lisbon, and it was important to preserve the architectural style of the building. The windows fit perfectly into our interior decor. However, the main advantage was the efficiency. We are happy that the team truly dedicated themselves to our project and managed to install the windows in less than a month.

– Sergio Farinha

We were updating the windows for a building used as an Airbnb hotel in Ponta Delgada. Aesthetics were important to us, so we chose to install Reynaers aluminum windows. They withstand the aggressive maritime climate very well and have a high level of energy efficiency. Moreover, we were very pleased with the communication with the managers. It was welcoming and professional.

– Fia Gonçalves

We agreed to use aluminum windows with the Schüco profile, one of the most prestigious profile systems, and we have not regretted this choice at any moment. About a month after the contract was signed, the installation process began. I would also like to highlight that the company is part of the state program Class+, which allowed us to be reimbursed nearly 2000 euros for the replacement of the windows. This company is truly advantageous and professional.

– Diogo Fernandes

I was pleasantly surprised by the level of service and the quality of the windows. We opted for conventional PVC windows. The price was approximately the same as that of other competing companies. We chose MaxiGlass because they responded quickly and offered a 10-year warranty with no additional maintenance costs. We have already noticed a 20% reduction in energy expenses. I regret not replacing the old windows earlier.

– Manuela Ferreira

I am grateful to the team at MaxiGlass. I would especially like to highlight the manager Olesya. She was very helpful and professional. I chose Aluprof aluminum windows for my country house, as they suited the project design better. These windows have a very elegant and modern look. I also immediately noticed a good level of sound insulation. Thank you for the quality work and careful installation.

– Bruno Coutinho

Our apartment is located in the historic center of Lisbon, and it was important to preserve the architectural style of the building. The windows fit perfectly into our interior decor. However, the main advantage was the efficiency. We are happy that the team truly dedicated themselves to our project and managed to install the windows in less than a month.

– Sergio Farinha

We were updating the windows for a building used as an Airbnb hotel in Ponta Delgada. Aesthetics were important to us, so we chose to install Reynaers aluminum windows. They withstand the aggressive maritime climate very well and have a high level of energy efficiency. Moreover, we were very pleased with the communication with the managers. It was welcoming and professional.

– Fia Gonçalves

We agreed to use aluminum windows with the Schüco profile, one of the most prestigious profile systems, and we have not regretted this choice at any moment. About a month after the contract was signed, the installation process began. I would also like to highlight that the company is part of the state program Class+, which allowed us to be reimbursed nearly 2000 euros for the replacement of the windows. This company is truly advantageous and professional.

– Diogo Fernandes

I was pleasantly surprised by the level of service and the quality of the windows. We opted for conventional PVC windows. The price was approximately the same as that of other competing companies. We chose MaxiGlass because they responded quickly and offered a 10-year warranty with no additional maintenance costs. We have already noticed a 20% reduction in energy expenses. I regret not replacing the old windows earlier.

– Manuela Ferreira

I am grateful to the team at MaxiGlass. I would especially like to highlight the manager Olesya. She was very helpful and professional. I chose Aluprof aluminum windows for my country house, as they suited the project design better. These windows have a very elegant and modern look. I also immediately noticed a good level of sound insulation. Thank you for the quality work and careful installation.

– Bruno Coutinho

Our apartment is located in the historic center of Lisbon, and it was important to preserve the architectural style of the building. The windows fit perfectly into our interior decor. However, the main advantage was the efficiency. We are happy that the team truly dedicated themselves to our project and managed to install the windows in less than a month.

– Sergio Farinha

We were updating the windows for a building used as an Airbnb hotel in Ponta Delgada. Aesthetics were important to us, so we chose to install Reynaers aluminum windows. They withstand the aggressive maritime climate very well and have a high level of energy efficiency. Moreover, we were very pleased with the communication with the managers. It was welcoming and professional.

– Fia Gonçalves

We agreed to use aluminum windows with the Schüco profile, one of the most prestigious profile systems, and we have not regretted this choice at any moment. About a month after the contract was signed, the installation process began. I would also like to highlight that the company is part of the state program Class+, which allowed us to be reimbursed nearly 2000 euros for the replacement of the windows. This company is truly advantageous and professional.

– Diogo Fernandes

I was pleasantly surprised by the level of service and the quality of the windows. We opted for conventional PVC windows. The price was approximately the same as that of other competing companies. We chose MaxiGlass because they responded quickly and offered a 10-year warranty with no additional maintenance costs. We have already noticed a 20% reduction in energy expenses. I regret not replacing the old windows earlier.

– Manuela Ferreira

I am grateful to the team at MaxiGlass. I would especially like to highlight the manager Olesya. She was very helpful and professional. I chose Aluprof aluminum windows for my country house, as they suited the project design better. These windows have a very elegant and modern look. I also immediately noticed a good level of sound insulation. Thank you for the quality work and careful installation.

– Bruno Coutinho

Our apartment is located in the historic center of Lisbon, and it was important to preserve the architectural style of the building. The windows fit perfectly into our interior decor. However, the main advantage was the efficiency. We are happy that the team truly dedicated themselves to our project and managed to install the windows in less than a month.

– Sergio Farinha

We were updating the windows for a building used as an Airbnb hotel in Ponta Delgada. Aesthetics were important to us, so we chose to install Reynaers aluminum windows. They withstand the aggressive maritime climate very well and have a high level of energy efficiency. Moreover, we were very pleased with the communication with the managers. It was welcoming and professional.

– Fia Gonçalves

What our clients say:

We agreed to use aluminum windows with the Schüco profile, one of the most prestigious profile systems, and we have not regretted this choice at any moment. About a month after the contract was signed, the installation process began. I would also like to highlight that the company is part of the state program Class+, which allowed us to be reimbursed nearly 2000 euros for the replacement of the windows. This company is truly advantageous and professional.

– Diogo Fernandes

I was pleasantly surprised by the level of service and the quality of the windows. We opted for conventional PVC windows. The price was approximately the same as that of other competing companies. We chose MaxiGlass because they responded quickly and offered a 10-year warranty with no additional maintenance costs. We have already noticed a 20% reduction in energy expenses. I regret not replacing the old windows earlier.

– Manuela Ferreira

I am grateful to the team at MaxiGlass. I would especially like to highlight the manager Olesya. She was very helpful and professional. I chose Aluprof aluminum windows for my country house, as they suited the project design better. These windows have a very elegant and modern look. I also immediately noticed a good level of sound insulation. Thank you for the quality work and careful installation.

– Bruno Coutinho

Our apartment is located in the historic center of Lisbon, and it was important to preserve the architectural style of the building. The windows fit perfectly into our interior decor. However, the main advantage was the efficiency. We are happy that the team truly dedicated themselves to our project and managed to install the windows in less than a month.

– Sergio Farinha

We were updating the windows for a building used as an Airbnb hotel in Ponta Delgada. Aesthetics were important to us, so we chose to install Reynaers aluminum windows. They withstand the aggressive maritime climate very well and have a high level of energy efficiency. Moreover, we were very pleased with the communication with the managers. It was welcoming and professional.

– Fia Gonçalves

We agreed to use aluminum windows with the Schüco profile, one of the most prestigious profile systems, and we have not regretted this choice at any moment. About a month after the contract was signed, the installation process began. I would also like to highlight that the company is part of the state program Class+, which allowed us to be reimbursed nearly 2000 euros for the replacement of the windows. This company is truly advantageous and professional.

– Diogo Fernandes

I was pleasantly surprised by the level of service and the quality of the windows. We opted for conventional PVC windows. The price was approximately the same as that of other competing companies. We chose MaxiGlass because they responded quickly and offered a 10-year warranty with no additional maintenance costs. We have already noticed a 20% reduction in energy expenses. I regret not replacing the old windows earlier.

– Manuela Ferreira

I am grateful to the team at MaxiGlass. I would especially like to highlight the manager Olesya. She was very helpful and professional. I chose Aluprof aluminum windows for my country house, as they suited the project design better. These windows have a very elegant and modern look. I also immediately noticed a good level of sound insulation. Thank you for the quality work and careful installation.

– Bruno Coutinho

Our apartment is located in the historic center of Lisbon, and it was important to preserve the architectural style of the building. The windows fit perfectly into our interior decor. However, the main advantage was the efficiency. We are happy that the team truly dedicated themselves to our project and managed to install the windows in less than a month.

– Sergio Farinha

We were updating the windows for a building used as an Airbnb hotel in Ponta Delgada. Aesthetics were important to us, so we chose to install Reynaers aluminum windows. They withstand the aggressive maritime climate very well and have a high level of energy efficiency. Moreover, we were very pleased with the communication with the managers. It was welcoming and professional.

– Fia Gonçalves

We agreed to use aluminum windows with the Schüco profile, one of the most prestigious profile systems, and we have not regretted this choice at any moment. About a month after the contract was signed, the installation process began. I would also like to highlight that the company is part of the state program Class+, which allowed us to be reimbursed nearly 2000 euros for the replacement of the windows. This company is truly advantageous and professional.

– Diogo Fernandes

I was pleasantly surprised by the level of service and the quality of the windows. We opted for conventional PVC windows. The price was approximately the same as that of other competing companies. We chose MaxiGlass because they responded quickly and offered a 10-year warranty with no additional maintenance costs. We have already noticed a 20% reduction in energy expenses. I regret not replacing the old windows earlier.

– Manuela Ferreira

I am grateful to the team at MaxiGlass. I would especially like to highlight the manager Olesya. She was very helpful and professional. I chose Aluprof aluminum windows for my country house, as they suited the project design better. These windows have a very elegant and modern look. I also immediately noticed a good level of sound insulation. Thank you for the quality work and careful installation.

– Bruno Coutinho

Our apartment is located in the historic center of Lisbon, and it was important to preserve the architectural style of the building. The windows fit perfectly into our interior decor. However, the main advantage was the efficiency. We are happy that the team truly dedicated themselves to our project and managed to install the windows in less than a month.

– Sergio Farinha

We were updating the windows for a building used as an Airbnb hotel in Ponta Delgada. Aesthetics were important to us, so we chose to install Reynaers aluminum windows. They withstand the aggressive maritime climate very well and have a high level of energy efficiency. Moreover, we were very pleased with the communication with the managers. It was welcoming and professional.

– Fia Gonçalves

We agreed to use aluminum windows with the Schüco profile, one of the most prestigious profile systems, and we have not regretted this choice at any moment. About a month after the contract was signed, the installation process began. I would also like to highlight that the company is part of the state program Class+, which allowed us to be reimbursed nearly 2000 euros for the replacement of the windows. This company is truly advantageous and professional.

– Diogo Fernandes

I was pleasantly surprised by the level of service and the quality of the windows. We opted for conventional PVC windows. The price was approximately the same as that of other competing companies. We chose MaxiGlass because they responded quickly and offered a 10-year warranty with no additional maintenance costs. We have already noticed a 20% reduction in energy expenses. I regret not replacing the old windows earlier.

– Manuela Ferreira

I am grateful to the team at MaxiGlass. I would especially like to highlight the manager Olesya. She was very helpful and professional. I chose Aluprof aluminum windows for my country house, as they suited the project design better. These windows have a very elegant and modern look. I also immediately noticed a good level of sound insulation. Thank you for the quality work and careful installation.

– Bruno Coutinho

Our apartment is located in the historic center of Lisbon, and it was important to preserve the architectural style of the building. The windows fit perfectly into our interior decor. However, the main advantage was the efficiency. We are happy that the team truly dedicated themselves to our project and managed to install the windows in less than a month.

– Sergio Farinha

We were updating the windows for a building used as an Airbnb hotel in Ponta Delgada. Aesthetics were important to us, so we chose to install Reynaers aluminum windows. They withstand the aggressive maritime climate very well and have a high level of energy efficiency. Moreover, we were very pleased with the communication with the managers. It was welcoming and professional.

– Fia Gonçalves

Implemented projects

Futago House

BC Platform

Tetris Hall

Arena Tower

Aeroporto de Kyiv (Zhulyany)

Porsche Centre Kyiv Airport

Private residence

Futago House

BC Platform

Tetris Hall

Arena Tower

Aeroporto de Kyiv (Zhulyany)

Porsche Centre Kyiv Airport

Private residence

Futago House

BC Platform

Tetris Hall

Arena Tower

Aeroporto de Kyiv (Zhulyany)

Porsche Centre Kyiv Airport

Private residence

Futago House

BC Platform

Tetris Hall

Arena Tower

Aeroporto de Kyiv (Zhulyany)

Porsche Centre Kyiv Airport

Private residence

Implemented projects

Futago House

BC Platform

Tetris Hall

Arena Tower

Aeroporto de Kyiv (Zhulyany)

Porsche Centre Kyiv Airport

Private residence

Futago House

BC Platform

Tetris Hall

Arena Tower

Aeroporto de Kyiv (Zhulyany)

Porsche Centre Kyiv Airport

Private residence

Futago House

BC Platform

Tetris Hall

Arena Tower

Aeroporto de Kyiv (Zhulyany)

Porsche Centre Kyiv Airport

Private residence

Futago House

BC Platform

Tetris Hall

Arena Tower

Aeroporto de Kyiv (Zhulyany)

Porsche Centre Kyiv Airport

Private residence

Implemented projects

Futago House

BC Platform

Tetris Hall

Arena Tower

Aeroporto de Kyiv (Zhulyany)

Porsche Centre Kyiv Airport

Private residence

Futago House

BC Platform

Tetris Hall

Arena Tower

Aeroporto de Kyiv (Zhulyany)

Porsche Centre Kyiv Airport

Private residence

Futago House

BC Platform

Tetris Hall

Arena Tower

Aeroporto de Kyiv (Zhulyany)

Porsche Centre Kyiv Airport

Private residence

Futago House

BC Platform

Tetris Hall

Arena Tower

Aeroporto de Kyiv (Zhulyany)

Porsche Centre Kyiv Airport

Private residence

Implemented projects

Futago House

BC Platform

Tetris Hall

Arena Tower

Aeroporto de Kyiv (Zhulyany)

Porsche Centre Kyiv Airport

Private residence

Futago House

BC Platform

Tetris Hall

Arena Tower

Aeroporto de Kyiv (Zhulyany)

Porsche Centre Kyiv Airport

Private residence

Futago House

BC Platform

Tetris Hall

Arena Tower

Aeroporto de Kyiv (Zhulyany)

Porsche Centre Kyiv Airport

Private residence

Futago House

BC Platform

Tetris Hall

Arena Tower

Aeroporto de Kyiv (Zhulyany)

Porsche Centre Kyiv Airport

Private residence

Need help? Contact us for quick answers!

Need help? Contact us for quick answers!

Need help? Contact us for quick answers!

Need help? Contact us for quick answers!

Need help? Contact us for quick answers!

Need help? Contact us for quick answers!

Need help? Contact us for quick answers!

Need help? Contact us for quick answers!

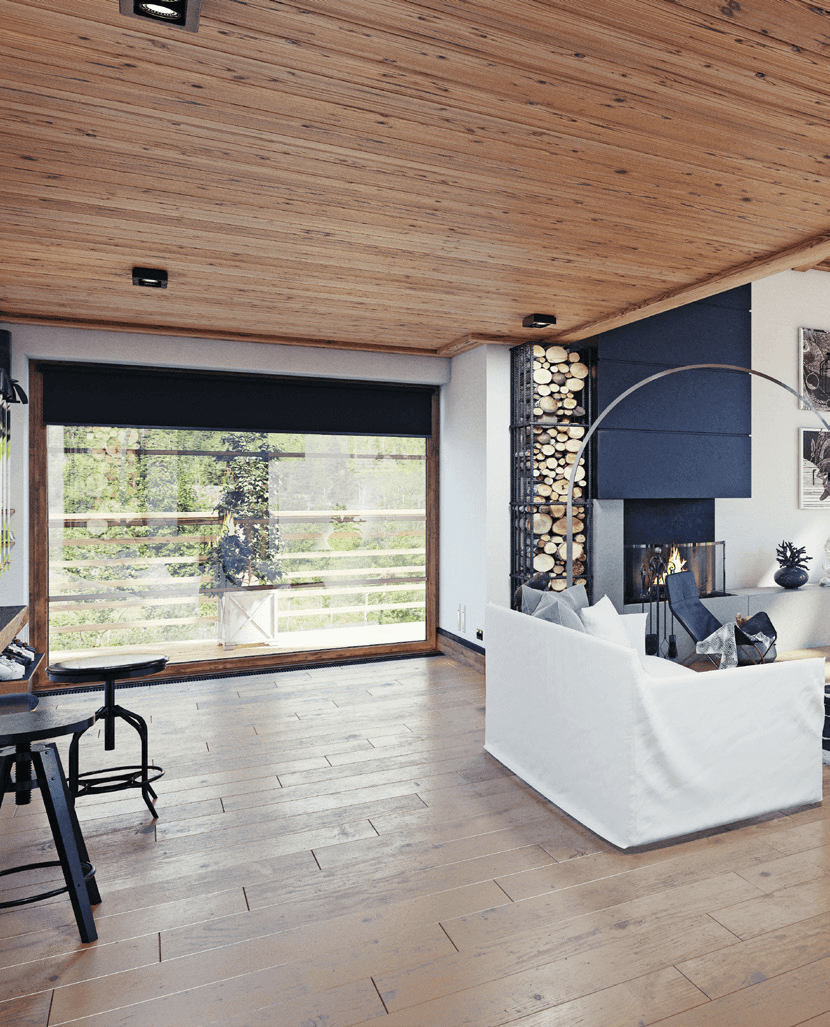

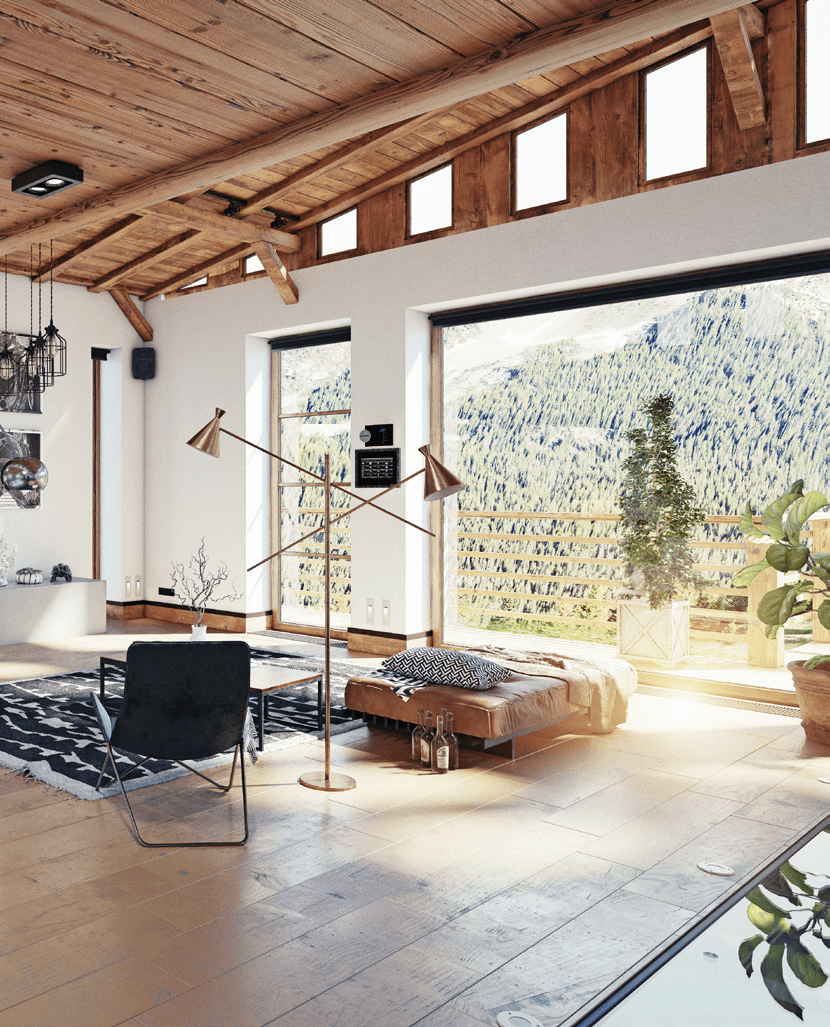

Experience the Timeless Elegance of Wooden Windows

Enhance your home with the warmth and sophistication of our wooden window collection. Crafted with precision and a commitment to sustainability, our wooden windows combine classic aesthetics with modern performance.

Main features:

Natural beauty: Each wooden window is a masterpiece, showcasing the unique character of the wood, making it a focal point in any room.

Energy efficiency: With superior insulation properties, our wooden windows keep your interiors comfortable year-round, reducing energy costs.

Longevity: Built to last, our wooden windows are treated to withstand wear, ensuring that their beauty and functionality endure for years.

Customization: Tailor your windows to your style with various wood species, designs, and finishes.

Why Choose Our Wooden Windows?

At Maxiglass, we take pride in offering high-quality wooden windows that stand the test of time. With a deep commitment to sustainable practices, we provide a window solution that is not only stylish but also environmentally responsible.

Discover the beauty and performance of wooden windows. Contact us today to explore our collection and let us transform your home into an inviting and charming paradise.